Natural

Latex tubing has been used extensively in the health care industry.

Known for its extreme flexibility, the applications has been expand

to the other applications such as Drain tubing, Model glider launching,

Exercise devices, Elastic band, Slingshots, Tourniquet bands, Non-aerol

can lines etc. Natural

Latex tubing has been used extensively in the health care industry.

Known for its extreme flexibility, the applications has been expand

to the other applications such as Drain tubing, Model glider launching,

Exercise devices, Elastic band, Slingshots, Tourniquet bands, Non-aerol

can lines etc.

Manufacturing Process (using Heat-sensitised latex

compound)

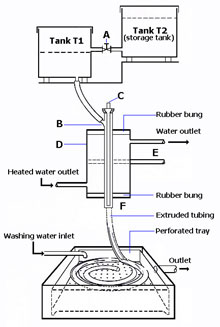

The basic requirements needed are Compounding Tank, Glass extrusion

apparatus, Perforated trays and Washing, chlorinating and drying facilities

(Referring to diagram)

- Compounding of latex

Latex is first de-ammoniated using formaldehyde

to provide a base compound ready for heat.

- Addition of heat-sensitising agent

To prepare heat-sensitised compound, heat-sensitise

agent is added to base compound. Blend thoroughly, then allow to

stand for removal of bubbles. The heat-sensitised compound is stored

in a storage tank (storage temperature should be kept at 20°C

or slightly lower).

- Extrusion

Compound from tank T1 is allowed to flow through

the glass extrusion tube (B) over a fixed glass core (C). The extrusion

tube is surrounded by a water jacket (D) through which water at

50°C - 60°C is circulated to gel the tubing. An adjustable

support (E) is fitted so that the height and consequently the gravity

head of compound, can be adjusted slightly to maintain even flow.

The tube emerges from the outlet (F) is in a firm gelled state.

- Washing

The gelled tubing is led directly into a perforated

tray immersed in a tank of cold running water. The tubing may be

cut off from the extrusion outlet and the tray is removed to another

washing tank. Production may continue collecting more tubing in

another tray. Time required for washing depends upon the thickness

of the tubing, but is typically about 4 hours.

- Chlorinating process

Chlorinating helps to reduce surface tack and

preserve the general appearance of the tubing. The tubing should

be immersed in the chlorinating solution for about 8 minutes. Provision

should also be made for the chlorinating solution to circulate through

the tubing when long lengths of tubing being processed. After chlorination,

the tubing should be thoroughly rinsed in clean water.

- Drying

After chlorinating process and rinsed, the tubing

should be dried in an oven or heated room at approximately 50-60°C.

The time required will depend upon the wall thickness and bore of

the tube, quantity of tubing being dried, oven efficiency etc.

|