Natural

rubber latex (NRL) is one of nature's most versatile materials and

the polymer of choice for medical devices. It is a cost-effective

material that provides good barrier properties, durability and comfort.

However, the emergence of latex protein allergy has generated adverse

publicity on the acceptability of NRL in the health care sector

by anti-latex lobby. This has prompted extensive R & D efforts to

reduce the incidence of allergy and ensure that NRL medical gloves

are of minimum health risk.

One of the solutions to address the latex protein allergy is to

use low protein NR latex (LOPROL). This type of latex can be prepared

by treating latex with proteolytic enzyme or a suitable surfactant

and purification process by dilution, centrifugation or membrane

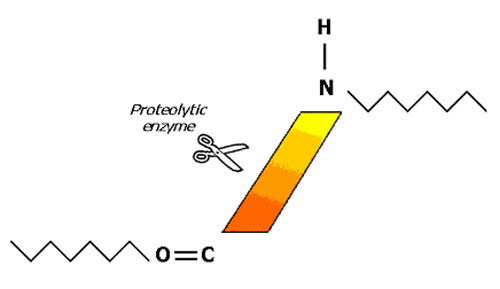

separation. The reaction mechanism for breakdown of polypeptide

chain by enzyme is shown below.

Enzyme Reaction on Protein Molecule

Manufacturing Process

A. Enzyme Treatment

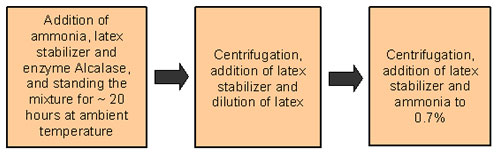

The MRB has developed several processes of producing low protein

NR latices using proteolytic enzymes such as Alcalase or Savinase.

The flowchart below shows one of the processes of producing low

protein NR latex.

B. Non-enzymatic process

B. Non-enzymatic process

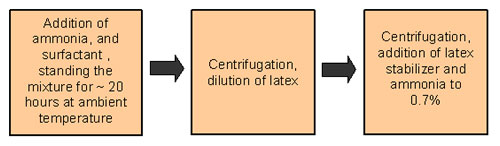

The MRB has also developed several processes of producing low protein

NR lattices using non-enzymatic process. The flowchart below shows

a typical non-enzymatic processes of producing low protein NR latex.

Properties

Properties

The nitrogen content of low protein latex prepared using enzymatic

and non-enzymatic process is in the range 0.05% - 0.09% and 0.02%

- 0.06% respectively. The extractable protein content of wet-gel

leached plus post dry-leached films prepared from these two type

of latices is less than 100 g/g. The physical properties of sulphur

vulcanised films prepared from these latices are comparable to those

prepared from normal NR latex concentrate.

|