The

MRB has developed a new generation peroxide prevulcanised NR latex

that produces product with improved ageing resistance, stable colour

during drying and low level of extractable proteins. Treatment of

this material produces products with low extractable protein and allergenic

protein contents. The

MRB has developed a new generation peroxide prevulcanised NR latex

that produces product with improved ageing resistance, stable colour

during drying and low level of extractable proteins. Treatment of

this material produces products with low extractable protein and allergenic

protein contents.

There are

three important approaches to produce low nitrosamine latex products:

- Using low nitrosamine accelerator system such as zinc dibenzyldithiocarbamate/zinc

mercaptobenzothiazole

- Peroxide prevulcanised NR latex, and

- Radiation vulcanised NR latex. The level of nitrosamine in latex

products could also be reduced to a certain degree by surface

treatment and washing of latex films. The concern of non-volatile

nitrosamines and cytotoxicity of additives used in latex product

may affect future acceptability of the zinc dibenzyldithiocarbamate/zinc

mercaptobenzothiazole system.

There are other advantages of producing products from peroxide

prevulcanised latex or radiation vulcanised latex. Unlike those

prepared using accelerated latex vulcanising systems, peroxide or

radiation vulcanised latex does not contain vulcanising accelerators

that could cause type IV allergic reactions, zinc compounds that

pose disposal problem of products, nor sulphur containing compounds

that make the product unsuitable for applications in the electronic

industry and safe product disposal by incineration.

Manufacturing Process

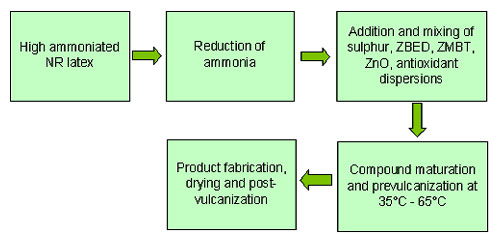

A. Using ZBED (zinc dibenzyl dithiocarbamate)

/ ZMBT (zinc mercaptobenzothiazole) accelerated sulphur vulcanising

system

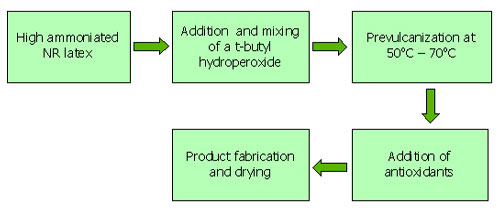

B. Using peroxide prevulcanised NR latex

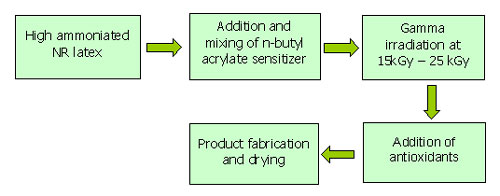

C. Using radiation vulcanised NR latex

|