Paddy has

to be dehusked and polished to convert it into the marketable form

of white rice. In the past, dehusking of the paddy was done manually

by pounding the paddy in a receptacle with a wooden stump. This was

later replaced by mechanical dehusking with the use of rubber rollers,

which gave a greater dehusking efficiency and less grain breakage.

When Malaysia started her factories in the 1970's, the rollers produced

were based on silica-filled styrene-butadiene rubber (SBR) compounds

because of their longer service life and better thermal stability

compared to natural rubber (NR) rollers. However, lately many alternative

materials such as acrylonitrile rubber especially the carboxylated

grades, polychloroprene rubbers, EPDM, etc. were being used to give

even longer service life than the SBR rollers.

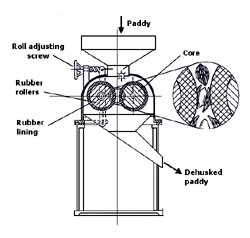

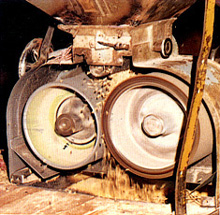

In a modern rice miller, a pair of rubber-lined

rollers are mounted in an enclosed chamber and driven at a friction

ratio (figure 1). A typical unit using 254 mm nominal width

x 254 mm outer diameter rollers run at 1.28 : 1 friction ratio with

the faster roller at 900 revolutions per minute. The nip of the rollers

is manually adjusted during dehusking to compensate for the gradual

abrasion of the rubber surface and its thermal softening. The paddy

in passing through the rollers nip is subjected to both compressive

and shearing forces. When these forces are correctly predetermined

for a particular grade of paddy (by rubber hardness, resilience, rollers

nip, speed and friction ratio) the paddy will remain substantially

intact after going through, while the husk is broken off. In practice,

the dehusking efficiency can be as high as 90% per pass.

|

Figure1: Paddy dehusking machine

|

Rice millers are often run between 15 to 24 hours

a day non-stop and causes the roller temperature reaching up to 80°C.

Taking into account the above factors, the compound design of a paddy-dehusking

roller should satisfy the following criteria:

- Low cost

- Easy processing

- Good service life

- Good dehusking efficiency which determined by roller hardness

usually 93±3 IRHD, etc.

- Good final product i.e. white rice

Manufacturing Process

There are a number of possible routes to manufacture

paddy dehusking rollers (see the flow chart). The most establish

process is that of mixing (two-roll mill or internal mixer), pre-warming,

calendaring, laminating to the metal core, preshaping, mould insertion

and autoclave curing. Press moulding is commercially practiced but

the economics of scale appear unfavourable. There are also possible

alternative routes such as the use of wrapped laminated nylon tape

thus dispensing with the use of moulds.

|

|

|

|